Materials

An exciting combination of natural materials and high tech

Every part of the Sandwichbike is designed solely for this bike and manufactured with great care for the product as well as the environment. But where does it all come from?

Wooden frame

The wood used for the Sandwichbike’s frame is beech plywood. Harvested in Germany, near a small town called Brakel to be exact. The factory producing the plywood is established right there, so there’s no need to drag trees all across the continent to get the Sandwichbike its frame.

The production process of Sandwichbikes wooden frame consists of 3 stages.

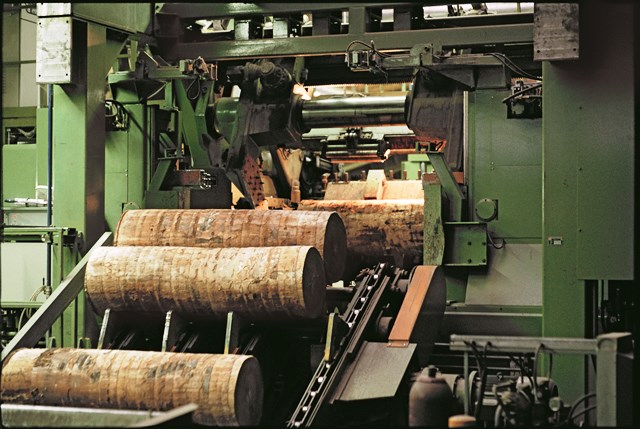

1st Stage: Veneer production

After being cut down in the local forest, the beech trunks are sprayed with water, so that the trunk wood maintains its quality. Before it goes into production, the trunk wood goes into steam pits where they are fanned by hot water vapour for 48 hours. Then the wood is soft enough for the peeling machine. After peeling, the wet veneers run through a belt dryer after which they are sorted electronically by quality before they move on to the next production stage.

2nd Stage: Pressing

Before the veneers are brought into shape, for the Sandwichbike frame, 15 layers are glued together with adhesion rollers. The bonded veneers are brought into shape in a press using high pressure. The adhesive hardens more quickly because the pressing tools are heated.

3nd Stage: Processing

The pressed plates are cut into equally wide shaped wood parts by CNC-controlled saws, making it as accurate as can be. As the finishing touch, the wooden plates of layered plywood are treated with a varnish that is breathable and UV-resistant so that Sandwichbikes is all weather proof.

Aluminium Parts

But how does it all stick together?

This is where the smart cylinders come in. The Sandwichbikes uses aluminium blocks for the frame. These carefully milled aluminum parts are what turns four wooden panels and two wheels into a Sandwichbike.

All Sandwichbikes Aluminium parts are carefully milled. The technical drawings deliver all the specifications and tolerances for the production.

You must be logged in to post a comment.